FILTRATION, OIL ANALYSIS AND FLUSHINGS

FILTRATION:

Do you know the level of cleanliness of your oil and your systems to give competitiveness and efficiency to your machinery?

Fluid contamination creates problems with the transmission of energy in the hydraulic system, reducing lubrication and sealing power.

An efficient filtration system allows to eliminate the risks of natural contamination present in the fluid (from the container), from the one created by the generating system (dust and various residues from processing) and from external infiltrations.

Fluid contamination creates problems with the transmission of energy in the hydraulic system, reducing lubrication and sealing power.

An efficient filtration system allows to eliminate the risks of natural contamination present in the fluid (from the container), from the one created by the generating system (dust and various residues from processing) and from external infiltrations.

ANALYSIS:

D.R.A. offers a complete analysis on three levels of the fluid also by means of Parker certification which allows to evaluate the efficiency status of your system.

BASIC ANALYSIS:

Definition of the contamination class according to ISO 4406 normative for the percentage of water.

At the customer with particle counter. 80 EURO

At our laboratory. 75 EURO

STANDARD ANALYSIS:

Automatic particle counting of the patch test and membrane photography.

Quantitative water determination by the Karl Fisher method.

Qualitative estimation of the contaminant. 139 EURO

At the Parker laboratory. 256 EURO

COMPLETE CHEMICAL ANALYSIS:

Automatic particle counting of the patch test and membrane photography.

Quantitative water determination by the Karl Fisher method.

Qualitative estimation of the contaminant. At the Parker laboratory.

Spectrometer for identification of wear metals and viscosity additives 40 and 100 index of viscosity.

BASIC ANALYSIS:

Definition of the contamination class according to ISO 4406 normative for the percentage of water.

At the customer with particle counter. 80 EURO

At our laboratory. 75 EURO

STANDARD ANALYSIS:

Automatic particle counting of the patch test and membrane photography.

Quantitative water determination by the Karl Fisher method.

Qualitative estimation of the contaminant. 139 EURO

At the Parker laboratory. 256 EURO

COMPLETE CHEMICAL ANALYSIS:

Automatic particle counting of the patch test and membrane photography.

Quantitative water determination by the Karl Fisher method.

Qualitative estimation of the contaminant. At the Parker laboratory.

Spectrometer for identification of wear metals and viscosity additives 40 and 100 index of viscosity.

INTERVENTION:

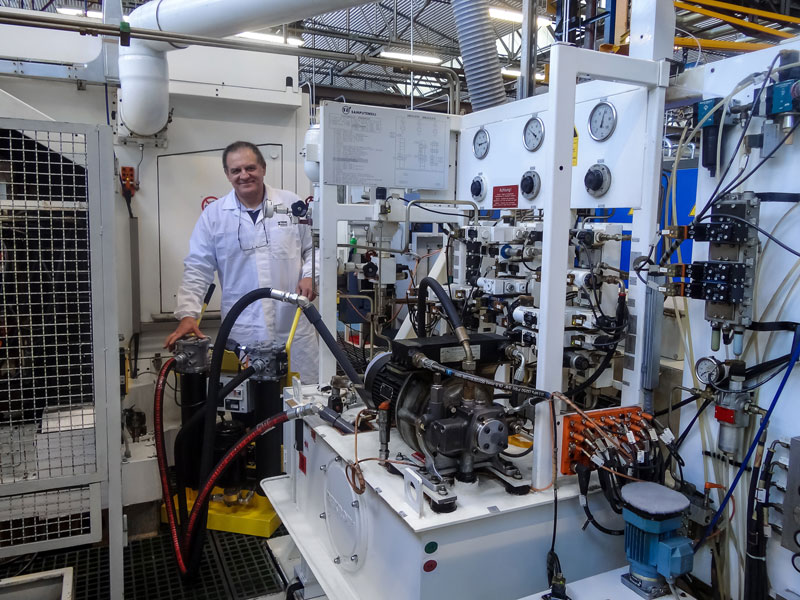

D.R.A. offers the flushing service to customers.

The intervention allows the elimination of contamination which is always followed by monitoring.

It is carried out with high quality and reliable machinery, bringing the following advantages to the oleo-dynamic system:

The intervention allows the elimination of contamination which is always followed by monitoring.

It is carried out with high quality and reliable machinery, bringing the following advantages to the oleo-dynamic system:

- Less wear of the components.

- Reduction of machine downtime and maintenance costs.

- Increased durability of oils.

- Better efficiency and use of machines.

ACCUMULATORS REPAIR AND RECHARGE

- Verification, preloading and recharge services through a nitrogen compressor.

- Repair and replacement of bags quickly thanks to the wide availability of replacement parts.

- Maintenance service and preloading control at customers

INTERVENTION OF REPLACING COMPONENTS AT THE CUSTOMER

Service at the customers for the replacement of pumps, motor pump units, hydraulic components and pipes on board of the machine.

English

English  Italiano

Italiano